JRS Glass offers high-quality machines and technology solutions for flat glass processing.

Our goal is to help create value for You with innovative machines, ideas and solutions

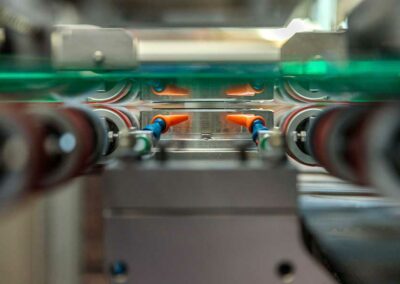

ONE: OUR SOLUTION FOR YOUR GLASS DRILLING, MILLING AND COUNTERSINKING NEEDS

ONE is a family of numerically controlled (CNC) machines for horizontal glass processing. It is capable of drilling, milling and countersinking operations on flat glass sheets, with thicknesses from 3 to 25 mm and, depending on the model, widths from 1350 mm to 2000 mm.

The ONE is designed to give you greater profitability, greater savings, and safety.

Strong investment in research and development and constant contact and listening to customers have enabled us to create a solid machine with high performance, fast, safe and easy to maintain.

Starting with the design, every aspect of the machine has been taken care of in every detail so that it will last for a long time and so that you can be assured of maximum convenience and ease of use. All systems (water, air etc etc…), for example, have been collected in easy-to-access locations. The user interface (HMI), and software are intuitive and schematic to make daily programming and operator training easy.

Highlights

Models

ONE 1.35

For glass with a maximum width of 1350mm

ONE 1.7

For glass with a maximum width of 1700mm

ONE 2.0

For glass with a maximum width of 2000mm

Safety

Machine body is fully enclosed and has interlocking doors: the operator has no access to moving parts during operations. All work is done inside. Water on the floor is also reduced by up to 90%.

Two smart solutions to increase the safety of You and Your operators

Versatility

Several possible machine configurations: you can change the configuration even after installation (left-to-right or right-to-left glass entry).

Do you want to change the layout of your plant? Want to insert or remove the ONE from a production line? You can do that and reposition it where it is most convenient for you

Yield

Being very compact in size ensures More production in a very small space compared to the size of the glass.

The space of a vertical machine with the technical advantages of the horizontal machine.

Power - High Performance

Capable of 15000 rpm with immediately available and constant torque. Thanks to these features, for example, you can perform faster machining or drill small diameters with high-quality results; Or process thicker glass .

Great performance and very high quality results.

Efficient

20 spindles in total: 10 tools per turret. Lots of tools to reduce the number of tool changes and/or increase the number of machining operations without interruption.

You can change a tool in less than 2 minutes and a spindle in less than 5 minutes.

Quality

Made in Italy with the best European, American and Japanese components.

Durable and Easy to Maintain

Designed to be durable, solid, simple in everyday operations and easy in daily maintenance.

Plug Play

Easy to install and use.

Intuitive human interface reduces and facilitates programming time. Software automatically creates production executives-just upload drawings directly.

Designed to minimize programming and operator training time

Profitable

It is compact, powerful, fast, efficient: in short, the machine with the highest profitability per square meter for your company.

Simply a machine that creates value for your company

Request information

JRS GLASS

Via Circonvallazione, 186/E3

10026 Santena (TO) – Italy